The pneumatic cylinders exploit the energy of the compressed air to obtain a linear movement of an object or part of the machine.

With a pressure not exceeding 10 bar, the cylinders can offer different push forces, by selecting the bore more indicated to the need, in fact, the thrust surface deriving from interior bore of the cylinder determines the force transmitted to the rod and thus to the part to be handled.

For the construction of the pneumatic cylinders, the most used material is aluminum, but it is also possible to have stainless steel cylinders.

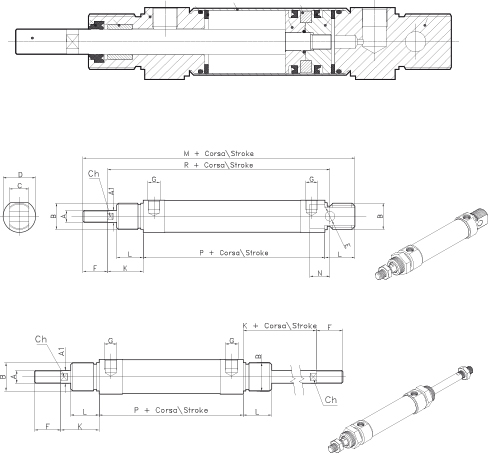

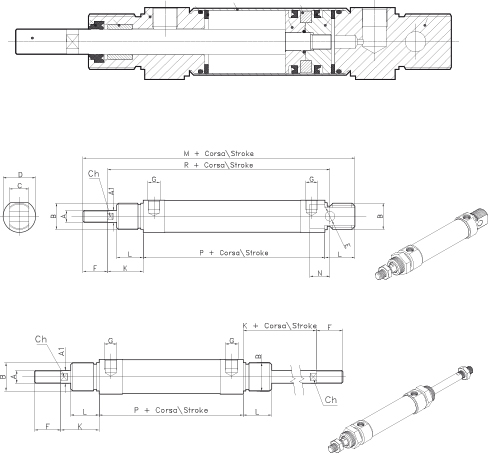

The most common versions are single rod or through rod, but there are many others such as: rotating rod, single effect, tandem push or tandem two strokes etc..

Applications

The pneumatic cylinders have many fields of application, the most common are: industry packaging machinery, woodworking machines, machine tools, bottling machines, machines for glass processing, machines for processing marble, assembly lines of cars, railway industry, the building industry, food industry, the petrochemical industry.

The compressed air energy is simple, economical and environmentally friendly and therefore perfect to meet the various application requirements.

Main Types

They can be of two types: cylinders ISO standard or not standard.

The ISO cylinders comply with international standard ISO 6432, ISO 15552, ISO 21287, while the cylinders are not complying to any norm may have shapes and dimensions free and not bound by dimensional rules.

The family of pneumatic cylinders not complying must meet the specific application needs, then each of them will present advantages but also disadvantages compared to others.

It is essential that the cylinder is properly evaluated for its technical characteristics as well as the performance by choosing the most suitable bore.

Cylinders that exploit the two rods to obtain a non-rotating plate and on which it is possible to mount auxiliary components such as pneumatic clamps or other.

They are available in all bores version of ISO 15552, from 32 to 100mm

Compact cylinders of the latest generation, the ISO 21287 is in fact a recently adopted legislation that regulates the compact dimensions of cylinders of this type.

With a wide range of bore sizes and versions, the compact cylinder ISO 21287 is the cylinder with the broadest range of applications.

The advantages are: compact size, ease of use, versatility, and cost-effectiveness of the product.

Compact cylinders of the latest generation, the ISO 21287 is in fact a recently adopted legislation that regulates the compact dimensions of cylinders of this type.

With a wide range of bore sizes and versions, the compact cylinder ISO 21287 is the cylinder with the broadest range of applications.

The advantages are: compact size, ease of use, versatility, and cost-effectiveness of the product.

It is a very particular type of cylinder as there are no sliding rods but rather a carriage that slides along the profile of the cylinder.

The available bores are 25, 32, 40, 50, 63 and strokes can reach a maximum of 6 meters.

They are available with standard carriage, short carriage, guided carriage and guided carriage with ball bearing.